|

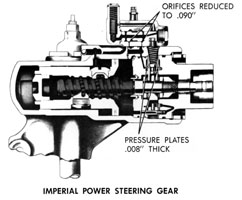

IMPERIAL STEERING GEAR INTERNAL CHANGES

- Ports in valve body .090" diameter (were .187") (Dampens road shock - reduces shimmy)

- Reaction pressure plates .008" thick (were .006") (Provides increased "road feel")

|

|

|

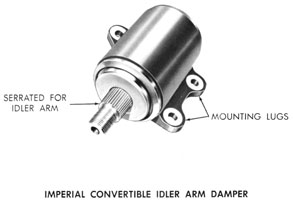

IMPERIAL CONVERTIBLE IDLER ARM DAMPER

- Bolted to bracket on frame side rail.

- Idler arm mounts on serrated shaft.

- Hydraulicly dampens rapid movement (shock or shimmy), but does not retard steering action.

- Rotates with same feel as shock absorber. Serviced by replacement only.

|

|

|

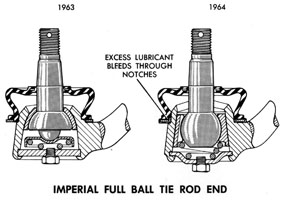

IMPERIAL FULL BALL TIE ROD ENDS

- Self adjusting, low friction, long life.

- 32,000 mile lubrication.

- Bleeding type seals.

|

|

|

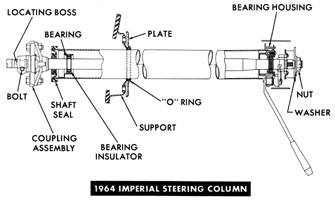

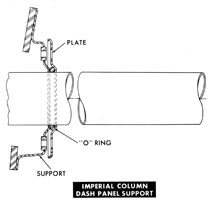

IMPERIAL STEERING COLUMN WITH LOWER BEARING

- Lower bearing with insulator.

- Coupling with 7 ply flexible disc.

- Floor support,"O" ring and plate.

- Install upper bearing housing (general design and service procedures same as other Corporation cars).

|

|

|

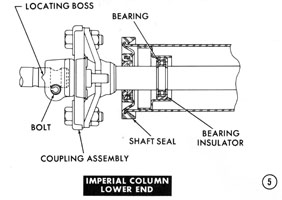

IMPERIAL COLUMN - LOWER END

- Position lower seal on shaft (lubricate seal).

- Center lower bearing on shaft serrations (lower bearing .007" larger I.D. than upper, and has red separator. Upper bearing has white separator or no separator).

- Install insulator on lower bearing and install shaft assembly in column.

|

|

|

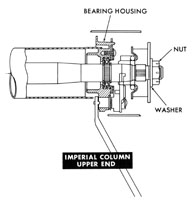

IMPERIAL COLUMN UPPER END

- Install snap ring, upper bearing and remaining parts (same procedure as 1963 V,L,P,D,C).

|

|

|

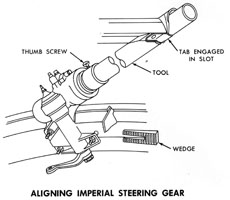

IMPERIAL GEAR AND COLUMN ALIGNMENT AND COLUMN INSTALLATION

- Gear must be realigned if mounting is disturbed.

- Loosely mount gear on side rail.

- With tool C-3949 bottomed on wormshaft support, and thumbscrew at 12 o�clock, tighten thumbscrew and install clamp at instrument panel with tab in slot.

- Tighten two front bolts, firmly position wedge by tapping lightly with hammer, then tighten rear bolt.

- Remove tool and install column assembly with:

- Master serrat ions aligned

- Locating pin in coupling bottomed against wormshaft (Install and tighten coupling bolt)

- Flexible coupling disc axially unstressed.

- Tab on instrument panel clamp engaged in slot.

- Do not let top of column fall or damage to coupling disc or horn wire will result.

|

|

- Tighten main support plate

- Slide "O" ring into place

- Tighten "0" ring retaining plate

|

|

|

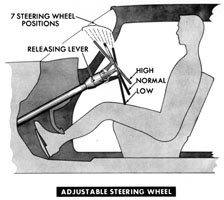

STEERING COLUMN WITh TILT WHEEL

- Optional on Imperial, Chrysler and Dodge 880.

- Raise release lever to select one of seven positions.

|

|

|

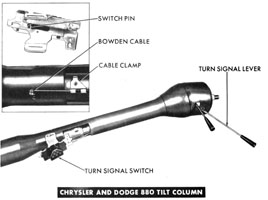

REMOVAL AND INSTALLATION OF TURN SIGNAL SWITCH

- Bowden cable engages switch pin.

- Switch screws tightened with wheel tilted down.

|

|

|

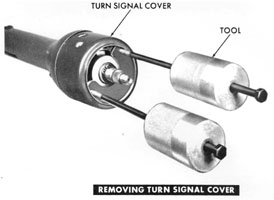

REMOVE TURN SIGNAL COVER

- Remove tilt and turn signal levers.

- Remove cover using tool #C-3954 and SP3426A weights.

|

|

|

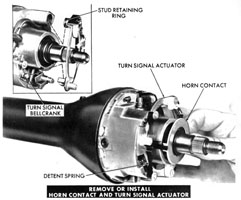

REMOVE OR INSTALL HORN CONTACT AND TURN SIGNAL YOKE

- Thread horn contact wire in or out carefully (observe routing during disassembly).

- Hold yoke squarely when engaging or disengaging pivot stud.

|

|

|

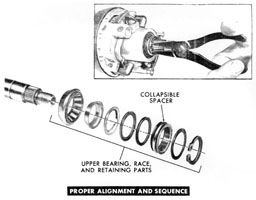

UPPER BEARING AND RELATED PARTS

- Collapsible spacer not reused (discard).

- Parts must be aligned and in sequence: upper bearing, inner race, bearing seat, retainer, rubber washer, collapsible spacer, washer, and snap ring.

|

|

|

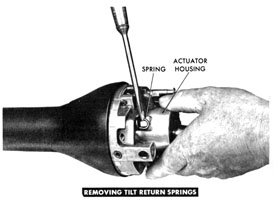

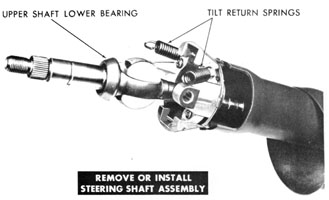

UNHOOK TILT RETURN SPRINGS

- Tilt to upward position to reduce tension.

|

|

|

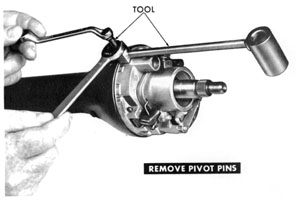

REMOVE ACTUATOR HOUSING PIVOT PINS

- Use tool #C-3957 - screw must not turn.

|

|

|

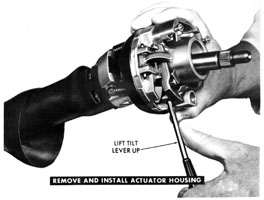

REMOVE OR INSTALL ACTUATOR

- Lift tilt lever so lock shoes will clear pins.

|

|

|

REMOVE OR INSTALL STEERING SHAFT

- Note position of lower bearing.

- Remove tilt return springs.

|

|

|

REMOVE OR INSTALL SPRING FROM SPHERICAL BEARING

- Tilt upper shaft approximately 10 degrees.

|

|

|

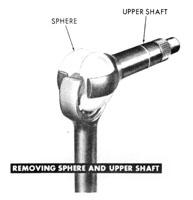

DISASSEMBLE OR ASSEMBLE STEERING SHAFT

- Turn upper shaft 90 degrees from centerline.

- Align flats on sphere with socket.

- Lift upper shaft and sphere from lower shaft. (Assemble in same position)

|

|

|

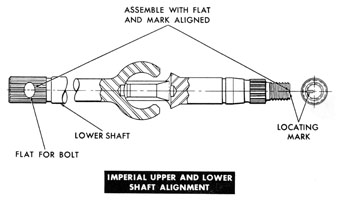

ALIGN SPLINES WHEN ASSEMBLING

- Imperial - Mark on upper shaft must be aligned with center of bolt groove (flat) on lower shaft.

- Chrysler and 880 - With mark on upper shaft at 12 o�clock, scribed mark in groove at lower end must be at 9 o�clock.

|

|

|

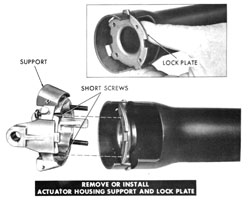

REMOVE OR INSTALL ACTUATOR HOUSING SUPPORT AND LOCK PLATE

- Note position of short screws.

- Lock plate slides in or out of slots.

|

|

|

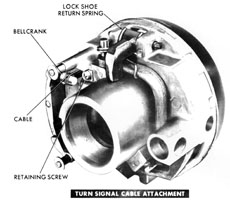

REMOVE OR INSTALL TURN SIGNAL SWITCH CONTROL CABLE

- Remove or install attaching screw.

- Disengage bowden wire from belicrank.

- Note position of bowden wire coils.

|

|

|

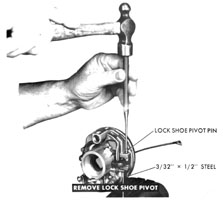

REMOVE OR INSTALL LOCK SHOE PIVOT PINS

- Back up boss with piece of steel.

- Use 1/8" punch.

|

|

|

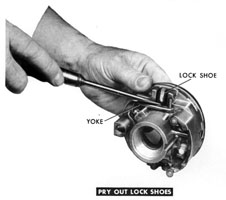

REMOVE OR INSTALL LOCK SHOES

- Carefully pry lock shoes over yoke with screw driver.

|

|

|

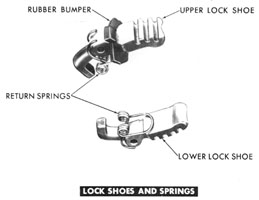

UPPER AND LOWER LOCK SHOES

- Upper lock shoe has three notches and rubber bumper. Lower lock shoe has four notches.

- Note position of tension springs.

|

|

|

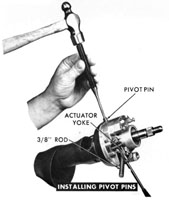

INSTALL ACTUATOR PIVOT PINS

- 3/8" rod under yoke helps align pin holes.

- Pins must be seated.

|

|

|

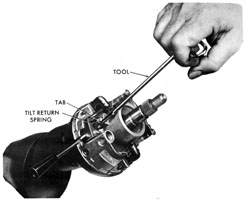

HOOK TILT RETURN SPRINGS OVER TABS

- Tilt to full upward position.

- Use tool C-3956.

- Spring ends must hook upward as shown.

|

|

|

INSTALL UPPER BEARING AND RELATED PARTS

- Use new collapsible spacer.

- Use tool C-3957.

- Parts must be aligned and in sequence: upper bearing, inner race, bearing seat, retainer, rubber washer, collapsible spacer, washer, snap ring.

- Snap ring must be fully seated.

|

|

|

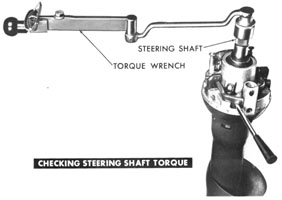

CHECK SHAFT ROTATING TORQUE

- Use inch pound torque wrench.

- Check in all tilt positions.

- If maximum reading is over 2 1/2 inch pounds, replace collapsible spacer.

|

|

|

INSTALL TURN SIGNAL COVER

|

|

|

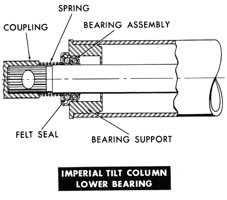

LOWER SHAFT BEARING - IMPERIAL ONLY

- Spring, bearing and plastic support held in place by coupling with bolt.

- Carefully pry out support to avoid breakage.

|

|

|