Imperial Home Page -> Repair -> Fuel-> 1981-1983 Tips -> EFI General Information

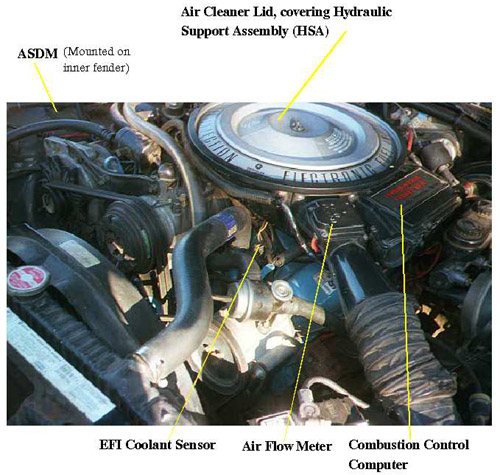

Indicated above are the locations of 5 items which are important to the operation of the EFI system.

General diagnosis information:

Make sure there are ABSOLUTELY NO air leaks from the "nozzle" of the air cleaner to

the FI support plate. This includes: CCC to air cleaner gasket, air cleaner base to EFI base gasket. (Both gaskets

tend to flatten-out and leak after 15-years or so, I made new ones). Although they are not "vacuum" leaks

per-say the car will act like they are. The amount of air is "metered" as it flows into the air cleaner, so any extra

air will make the car run lean.

Another typical EFI problem is "internal" vacuum leaks. Sort of like internal bleeding,

you'll never see it, but you'll notice the effects. The intake manifold gasket "leaks" between the lifter valley and

intake port. Because this system is SOOO sensitive, the car will idle and perform poorly. Noticed a big

improvement after replacing this gasket (big job, not fun).

If you suspect your car is running lean, try disconnecting the O2 sensor (one simple

wire). These cars are always running way too lean. Chrysler did that to squeeze the maximum mpg rating for the

EPA. No data from the O2 sensor will keep the fuel mix richer and help compensate for "vacuum leaks".

If your EFI system encounters any type of trouble, (air leaks, phases of the moon, etc.) it

will revert to a "lean-lock" condition. The cure is to disconnect the battery, pause, pray, re-connect the

battery. Don't bother with the huge re-cal procedure---An experienced EFI tech showed me why this is just a

waste-o-time formality. Any time it runs crappy, try this.

Question:

I have a 1982 Imperial. It would not start,

and couldn't hear fuel pump operation, so thought it might be that; but grounded

ASDM, and it started. Still can't hear fuel pump when first turn on key like

I could on others, but it started. The ASDM had a ground going to a spot about a

foot in front of it, that had three other wires grounded. This appears to be

factory grounded, and I don't know if it helped, or just was time for the darned

thing to start.

Reply:

Sometime in 82 Chrysler woke up to the grounding problem on the ASDM, and yours may be built after that date, thus the ground wire. But if it goes to

the fender sheet metal, I think it is still suspect. I would run a ground directly to something on the engine, I use the ground terminal on the

alternator, I think this is a much better ground.

I don't know why you are not hearing the fuel pump. It isn't clear if you mean the control pump in the HSA or the rear pump in the tank, but in either

case, you can see if it is getting voltage during cranking by putting a test light on the electrical feed. The feed to the rear pump is on the firewall,

there is a large resistor with green wires going to it, just put your test light from there to ground, it should light up whenever you are cranking

and after the engine starts, it will stay lit. Of course we know it is, because the car is running. The control pump is a little harder to check,

but if you have someone crank it while you probe the hot lead to the pump motor inside the HSA (of course you need the lid off to do this, unless you

get tricky and route a wire out through the air inlet), so it will not keep running, but you should see the light on momentarily every time you turn on

the key, and while you are cranking. You can tell from the manual which wire is the hot one, I forget the color now, but there are only two wires,

and one is ground.

If the light is not coming on when you first turn on the key, the fuel pressure switch has probably quit. Look for it on the fuel line from the

pump to the nozzle assembly, it has one wire clipped to it. If you take a test meter and measure the ohms from its terminal to ground with everything

off and the wire disconnected, you should measure 10 ohms or less. If you get way more than 10 ohms, you have a bad fuel pressure switch.

Question:

My 81 idles very rough, attempting to stop much of the time, but catches itself, and continues to roughly idle.

Did stop after rough idling for awhile, and three times started right up.

Fourth stop would not start, however if I push accelerator down does start momentarily, and runs down to stop. I

realize, pushing throttle down relieves a flooded condition, but can't believe it is flooded,

but maybe,

and maybe it was getting too much gas while was idling, and that caused rough idle. Black sooty residue accumulated

on cement from exhaust while

it was idling. Since I have three of these EFI units, guess I could start methodically

changing parts, but would like a little more information on the basics.

Reply:

The bad running at idle is usually one of two things. Since you see black

soot from the exhaust, I would suspect the fuel nozzles are not squirting a clean pattern. If you watch them while someone cranks the engine (pull the

center wire out of the distributor cap AND GROUND IT TO THE BLOCK while you do this so you don't get a flame in your face!) you can see the pattern.

There are 8 nozzles, I'll bet one of them is drizzling, or else there is a leak in the plumbing inside the air cleaner, and liquid gas it running into

the manifold. If you see a poor spray pattern, pull the nozzle assembly apart (watch those springs and "O" rings) and clean it out good, with spray

type carburetor cleaner until all 8 nozzles squirt clean.

The other possibility is an air leak somewhere. Make sure all the gaskets around the air cleaner assy. are good. This means the one sealing the power

module (7 wire) connector, the base gasket to the intake manifold, both above and below the throttle body, and the rim gasket around the lid, the

lower gasket on the base of the air cleaner housing, the clamp on the lid, the wing nut washer, and any gasketing around the CCC mounting hole. ANY

air leak, no matter how small, into the air cleaner assembly will screw up the engine's smoothness, especially at idle. If you suspect this problem,

try squirting WD40 around all the suspect orifices to see if you get any change in the idle.

Do you know how to run the engine with the lid off? This is a trick you can play on the computer by making it think you are cranking the engine, it

ignores the air flow sensor and lets the engine run with the lid off. This is very useful for working on the nozzles and the fuel pressure switch

problems.

By the way, when you get it running, how does it drive? Does it have normal power on the road?

My advice is to NOT start changing parts around. Let's figure out what is wrong with what you've got on it, then if you need to rob a part off

another setup, fine, but there is more likely hood of damaging something if we start fiddling around changing parts.

The Coolant Temperature Sensor's only duty is to inform the CCC when the water temp

is high enough for the engine to run on orders from the Oxygen Sensor.

If the engine is rough when cold, it is probably either too rich or too lean; use a vacuum gage to find where that is. Even in warm, ambient

temperatures, the heated air system must work, until the engine is warm. There is frequently icing at the throttle blades in spring time due to wet

air and high air velocity through the throttles, if the air is not being warmed; check out that system. A delay valve is provided in there to help it

all work better. Disable the EGR system and check for improved operation. If this is a high mileage car, the Intake ports are probably clogged and this

test will show nothing, unless the EGR valve itself has a leaking diaphragm.

Also check the 620 ohm resistor in the red wire to the CCC memory from the battery - must always show min of 10 volts between ground and the connector

at the memory, don't disconnect the connector at the memory. The other tips as to disconnecting the Oxygen sensor are for warmed engine

conditions. Finally, if the engine does not idle smooth at any time, remove all of the

vacuum hoses from the "Tree" at the rear of the engine, cap the nipples and

run it - see if that helps.

The problem with the vacuum powered air direction flaps relaxing toward some unenergized state is indeed, as you have already figured out, a

problem with low vacuum. These cars have a vacuum reservoir behind the right headlight that may not be doing its job, or your engine may be tired

enough that pulling hard really drops the vacuum more severely than the designers allowed for when the reservoir was sized.

Since you are suffering other symptoms of vacuum leaks, I think you would be well advised to take the air cleaner off the HSA so you can see the

vacuum "Tee" that comes out of the back of the intake manifold, and plug

every line that comes from it to see if it cleans up your idle. It would also be nice to know what your idle vacuum is. At sea level, or

thereabouts, you should be pulling at least 19", at idle. If you are not, there is definitely something wrong. Many of the possible leaks will be

masked by the EFI system, and of course would be inconsequential at anything above idle, since the main air flow would be so much greater,

this is consistent with your good results at high speed touring. You need to measure your vacuum at idle, and track down all the many places

where it can be leaking. These include the items connected to the Tee, plus the PCV system, the EGR valve, the throttle body gaskets, and the air

cleaner and HSA gasketing. Once the idle vacuum is known to be up to snuff, lets see what if any problems remain.

The poor throttle response at initial tip-in can be caused by an out of calibration Throttle Position Sensor, or by an incorrect EFI coolant

sensor, in addition to calibration problems in the power module, fuel flow meter, and control fuel pump, and of course, a large vacuum leak. This may

be very hard to find. One of my cars acts this way once in a while, then cures itself mysteriously. I have never been able to correlate the symptom

with anything. Just nature of the beast.

TO RUN THE ENGINE WITH THE AIR CLEANER REMOVED, you need to fool the CCC into thinking the car is cranking continuously. The way to do this is to pull

the small brown wire out of the multi-wire connector to the starter relay near the left hood hinge, and prepare a clip lead to connect that wire to

the +12 post of the battery, at the same time you start the engine. DO NOT CONNECT THE WIRE UNTIL THE STARTER IS CRANKING! All the time this wire

is connected, the EFI system will be delivering fuel into the intake manifold, you can get a big boom or even hydrostatic lock, which is even more

dangerous, if you leave it on there with the engine not running.

By the way, the engine will run, but not very well, and only at low RPM in this condition, since the air flow meter is ignored during "cranking". The

only reason to do this is to verify that the fuel rails and their connections are all ship shape, and all 8 of the fuel nozzles are squirting

fuel. You can't learn much else from this test.

OR, TO RUN THE ENGINE WITH THE AIR CLEANER REMOVED:

In troubleshooting for leaks, I thought of a technique for checking for leaks under the air cleaner lid which is pretty painless: After starting

the engine, one can unplug the 5 wire connector from the starter control relay on the firewall (near the power brake booster), the engine will

continue to run this way. Then one can take a probe of some sort and push it into the end of the particular wire in the 5 wire connector terminal

which tells the CCC to ignore the air flow reading (this is the smaller of the brown wires on the connector, the one in the middle of the longer leg of

the "L" shaped connector), and connect said probe to the positive post of

the battery. This fools the computer into letting you remove the lid of the air cleaner, and you can inspect for leaks etc. at your leisure. It is

VERY important that these steps be performed in exactly this order, any deviation may reward you with flying teeth off your ring gear!

This uses the same feature and connections as the previously published method for running the car with the lid off, but avoids having to push the

pins out of the connector, which is a chore I really would rather not have to face.

IN ORDER TO SMOOTH OUT THE UNEVEN IDLING CHARACTERISTICS:

A 270 Microhenry choke would be available from your local radio shack, it will look like a big resistor. It places an inductive reactor in series

with the O2 sensor, most likely the intent is to de-spike or "smooth out"

the signals from the sensor, perhaps the constant chattering which an O2 sensor puts out is bothersome to the CCC, but I would have thought that this

"chatter" or hunting from the O2 sensor was at a much slower rate than the

choke would affect. Perhaps the impedance of the circuit is much higher than a modern design. They did make that mistake in a couple of other parts

of the circuitry, most notably in the purge cycle timing circuit. As I've said before, this design was most likely a committee effort, with some of

the work done by creative but very junior circuit designers, and no review process.

This page was last updated on August 26, 2001. Send us your feedback, and come join the Imperial Mailing List - Online Car Club