Imperial Home Page -> Imperials by Year

-> 1957 -> Kerry's

Restoration

-> part 18

August 98

Over the past few weeks, I have had several distractions which kept me from my Imperial duties. Not the least of which was my oldest son moving out on his own. Damn I'm getting old....

At any rate, I did pick up some cheap blue tarps and hung them over the door of my 'lift room' so my old Air Conditioner would work. Boy, I have to tell you, if you live in hot country, spending $2 or 3 hundred bucks on an old central unit is the BEST tool you can have. 95 degrees and 90% humidity outside, 75 inside. nuff said. I don't even have a thermostat, just rigged up a light switch on the thermostat circuit as a on-off (turn it on when you come in and off when you go out...works for me)

In the last installment I had finished welding in the patch panel in the ruined door. Now I had to see if I could get the door skin back on. Remember I have never before pulled a door skin.

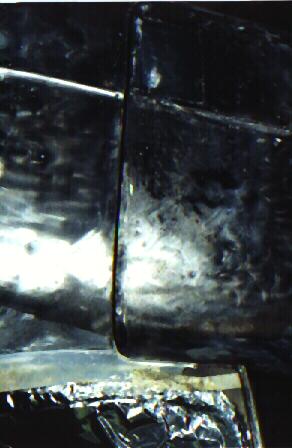

After laying the skin on the door frame and some prying it "popped" back into place. Magic! No warps, dents, or sags. I gently bent the flanges down a couple of times on each side to hold it in place and turned the door over. By the way, I have it on two sawhorses so it is at a comfortable working height.

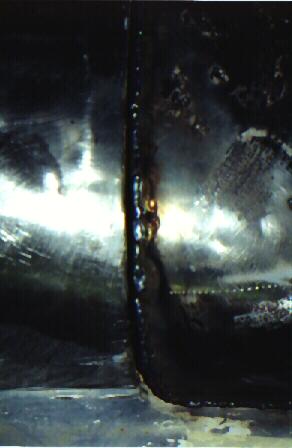

The next thing to do is rebuild the door frame where it was crumpled beyond repair. I cut a piece of 20 gauge and bent it using a variety of two by fours, and hammers to the required 80-90% bends. After trimming to fit, I MIG welded it in place with a series of spot welds. You should move from one side of the patch to the other while welding to keep warpage down. This repair is not very pretty on the inside front edge of the door but fortunately, it cannot be seen very easy and I will skim coat it with filler to hide the ugly.

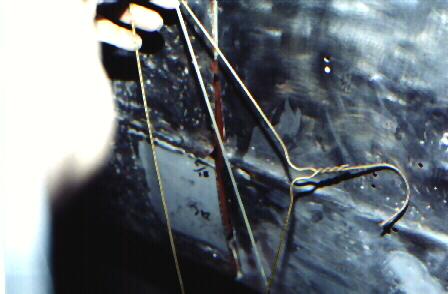

One last look for warp and I gently beat the remainder of the flanges down and tack welded each side in a couple of places. All that was left was the front edge. Due to all the damage, I did not have a folded metal seam, just a single part edge. This will be too sharp and fragile to hold up as a leading edge so I needed to make it "thicker" and stronger. Hummm..what to do. Going into my house (yes I took my shop shoes off first, I haven't been married for 27 years without learning a few things.) I found a very stout coat hanger that a winter coat had hung on. When all the bends were straightened, I had a nice 3/32 metal rod.

Not knowing the required gap to the front fender, I had to rehang the door and while I dreaded it, it turned out to be a piece of cake. Bolted right up and when I shut the door, I just tightened the bolts and everything worked fine. I sanded the coating off the wire and tacked it into place with the Mig, bending it to the desired contour and spacing it for the desired (1/8") gap. I then pulled the door back off and worked up and down the rod welding it solid. After welding I ground the welds down and volia a nice looking edge. Dang, this worked pretty well. I don't think a restoration shop could get away with it but after all, this is my car and while not original, I do not think ANYONE will be able to tell without very close inspection and I expect it will last as long as the rest of the door.

I decided to paint everything good with Corolless before I put it back together and started the body work. To do this, I also cut off the lower quarter behind the door and over the top of the right rear fender. This allowed me to get all the rot off and I will build new panels to weld in. I also soaked all the inner panels with Corolless. Since it was only noon and the paint had to sit 24 hours, I decided to strip the trunk lid. Carrying it outside and putting it on some sawhorses in the shade, I began to sandblast the old paint off. It may have been 40 years old and have some rusty spots but it was still tough!!! My sandblaster was too slow so I decided to get out my old HEAVY Black and Decker grinder and help the process along. This grinder is older than I am and weights a TON but it really works. I had a 6 inch backing pad and an 8 inch 36 grit disk. The only problem is that my back is beginning to hurt from holding the grinder off the surface of that huge decklid. Oh well, nearly done, just this last side.

Suddenly a mule kicked me right in the family jewels. I had let the grinder get over the edge of the decklid and the sanding disk caught, ripped, and bounced right up against my ...still running but now off balance and no longer round. By the time I turned it off, I could barely stand. I was actually afraid to look down, I just knew I had really messed myself up. Fortunately, there was no real damage, other than my pride. A little tender for a few days but other than that no lasting damage. I have always heard that you should wear a cup while grinding but that's just one of those old wives tales told by the safety geeks, right? I WILL be getting a cup! That hurt! Thought I was going to be singing tenor for sure!

The next day we had some family stuff to do and I still have not painted Corolless on the decklid. When I do, I have to turn it over and sandblast the inner lid. It has some pretty serious scales. There are also some pinholes in the Flytesweep but they will be covered by the stainless dish.

The problem is that I have passed the time when I was supposed to topcoat the Corolless. The can says that you need to scuff the paint if you wait more than 3 days but this will be very difficult because of all the nooks and crannies. I have posted a note on the IML about how to somehow etch the surface so a primer will adhere. Hopefully, someone will have some good ideas.

I'm going to say something now that will probably get me in trouble. The 57 (Katherine) is in much worse shape than I originally thought and will cost a lot more than I am willing (or she is worth) to put into her to bring her back "original". Given that I wanted an convertible anyway, I am SERIOUSLY considering doing a mild custom, including a lift off Carson style top. If I can find a suitable convertible frame, I might try to adapt it instead of the lift off style.

I grew up in the 60's reading all the hot rod and custom magazines...still do. I've always wanted to build a custom but never had the opportunity. This may be the best one in sight. I can hear the screaming already. Sorry if this idea is repugnant to some. Remember, this car does not have the right engine and the front and rear chrome is pretty sad. If you have never priced getting the front and rear chrome redone one something like a 57 you better sit down before you do.

At least it will be an IMPERIAL custom. If I decide to do it. I'm thinking of covering the rear seat with a tonneau cover similar to the 61 Tbird roadster.......ideas are welcome

I'm on the road for a few weeks so there will not be much progress for a while. When it cools down a little, I want to push it outside and finish stripping the paint so I can Corolless and prime it. I really want to drop the 440 in and get it mobile before winter.

KerryP

This page was last updated October 19, 2003. Send us your feedback, and come join the Imperial Mailing List - Online Car Club